11 Tips for Welding Aluminum in Shipbuilding

11 Tips for Welding Aluminum in the Shipbuilding Industry

By Frank G. Armao, Director, Aluminum Welding Technology

The Lincoln Electric Company

Aluminum alloys are lightweight and corrosion-resistant in marine environments, making the superior material for use in the shipbuilding industry.

There are two aspects that make general aluminum welding different from welding steel in the shipbuilding industry, and both are related to the fact that much of the welding is performed outdoors:

- Storage of aluminum plates and extrusions is critical to avoid oxidation

- Extra care must be taken to avoid breezes in the welding area

Both aspects will be discussed in more detail on the next few pages.

Know Which Aluminum Alloy You Are Welding

It isn’t enough to know that you are welding aluminum. Welding professionals have to know which alloy is about to be welded, and they have to know the correct filler metal to use. The most common alloys used in shipbuilding are the Al-Mg 5XXX sheet alloys and the Al-Mg-Si 6XXX extrusion alloys, primarily because of their excellent resistance to corrosion.

Most aluminum alloys are easily arc weldable. Virtually all of the alloys in the 1XXX, 3XXX, 4XXX, 5XXX and 6XXX series can be arc welded using GTAW and GMAW. However, most of the alloys in the 2XXX and 7XXX series cannot be arc welded. The only arc weldable alloys in the 2XXX series are 2219 and 2519. Almost all of the other 2XXX alloys will crack severely when welded. Similarly, the only alloys in the 7XXX family that can be arc welded are 7003, 7004, 7005 and 7039.

Specifically, be particularly wary of 2024 and 7075. It is tempting to buy one of these alloys for repair welding because they are strong and commonly available, but they are crack-sensitive to arc welding.

Welding an “unweldable" alloy or using the wrong filler alloy can result in immediate cracking or a premature failure in service at a later time.

When Should You Preheat?

Some people believe that all aluminum welds, both GTAW and GMAW, should be preheated. This isn’t true. In fact, if you have the correct equipment, preheat is rarely necessary.

Additionally, excessive preheat can severely degrade the mechanical properties. The last step in the heat treatment is aging, which is conducted at temperatures between 325 and 400°F. If you preheat to or above the aging temperature, you will ruin the alloy’s mechanical properties.

This is not to say that all preheating is bad. For example, if outside temperatures and humidity are very high, it is acceptable to preheat to 200°F to drive off moisture. Just don’t get carried away.

Storage of Aluminum Sheet, Plate and Extrusions

For most industries, the standard recommendation is to store aluminum inside prior to fabrication. While that is a good recommendation, it probably is unrealistic in the shipbuilding industry, where most welding is performed outside. There are more realistic storage recommendations for shipbuilding.

First, if at all possible, do not stack the aluminum plates in a flat stack on the ground. Storage in this way traps water between the sheets, increasing corrosion rates. Instead, stack the plates on edge to allow water to drain between the pieces. If sheets must be stacked flat, remove any paper interleaving or packing from between the plates. If left in place, the paper will act as a wick and draw water into between the plates. If the sheets are stacked flat, try not to stack one sheet directly on top of another. Instead, insert small wood or aluminum “stickers” between the sheets to let water drain.

All of this is intended to minimize the amount of corrosion, i.e., thick oxide that can form between the stored sheets. Any thick oxides will need to be mechanically removed before welding.

Make Sure You Clean the Parts Adequately Before Welding

Cleaning aluminum before welding consists of two separate and distinct operations. First, all oils, lubricants, machining coolants and other hydrocarbons used in manufacturing must be removed. Any hydrocarbons remaining on the material will get into the welding arc and release hydrogen gas, which causes weld porosity.

Removing hydrocarbons can be done in one of two ways. The most common is to wipe the plate with a clean rag saturated with a good degreasing solvent, such as acetone, toluene, MEK or carburetion cleaner. (Alcohols are not good degreasers and should not be used to clean aluminum.) Alternatively, but less common, the aluminum can be dipped into a tank containing a mild alkaline solution, then rinsed and dried.

Secondly, remove any heavy oxides from the aluminum before welding. This is normally done by hand or mechanically using a stainless steel wire brush. In cases where the materials are stored outside and develop a heavy gray oxide, it may be necessary to remove the oxide using a sanding or grinding disk.

Use the Correct Equipment

Before beginning each shift, welders should make sure the welding equipment is correctly set for aluminum. This is especially important if the equipment is interchangeably used to weld different materials.

Specifically for GMAW welding:

- Make sure the spool brake is not set too tight. Excessive tension will cause wire feeding problems. The brake should just be tight enough so that the spool doesn’t freewheel when the wire is stopped.

- Make sure the drive rolls are made for aluminum and have the correct diameter. Using V groove drive rolls, which are made to weld steel, on aluminum will deform the aluminum wire and cause feeding difficulties.

- Set the drive roll tension only tight enough so that the drive rolls don’t slip on the wire. Excessive tension will cause the filler wire to deform.

- Make sure the correct plastic inlet and outlet guide bushings are in place. Use of the steel parts used to feed steel wire will cause feeding problems.

- Make sure the gun liner is the correct plastic material used for aluminum. Use of the helical steel gun liner typically used to feed steel wire will take small shavings off the soft aluminum wire and cause the liner to clog up.

- Make sure the contact tip is the proper size for the aluminum wire being fed. Some people believe it is a good idea to use an oversized contact tip – for example, a 1/16-inch contact tip to feed 3/64-inch wire. DO NOT DO THIS. The tip must be of a size to freely pass the wire through but still tight enough to provide uniform electrical contact between the contact tip and wire. An oversized contact tip will not allow uniform current transfer, resulting in an excessive number of burnbacks.

Use the Correct Shielding Gas Flow Rate

Argon shielding gas flow rates should be a minimum of 35 SCFH for GMAW and 25 SCFH for GTAW. If a large diameter gas cup or gas nozzle is used, flow rates should be increased for both welding processes . If the welding is done outside, the shielding gas flow rates should be even higher – 45 SCFH minimum for GMAW and 35 SCFH for GTAW - because Argon gas is lighter than air and more susceptible to wind and breezes. The lack of shielding gas around the weld puddle will cause porosity. If the shielding gas is an argon/helium mix, the flow rates should be increased by about 25%, since helium provides little cleaning action.

Once the Weld Area Is Cleaned, Keep It Clean

Once the individual pieces are clean and fit up, make the weld as quickly as possible. The primary concern here is not that the parts will oxidize – at room temperature, aluminum oxidizes slowly if kept dry. The real worry is that dirt, oil, water vapor, etc. in the shop environment will contaminate the cleaned material. Once cleaned, fit and assembled, do not let the parts sit unprotected overnight or over the weekend. If the parts must remain unwelded for a period of time, put brown craft paper over the weld seam and tape it in place.

Store Welding Filler Wire Correctly

Aluminum filler wire should be stored in a clean, dry environment, preferably in its original packaging. Under such conditions, the wire has a usable shelf life of several years.

While the wire doesn’t need be stored in air-conditioned surroundings, it does help to store it in conditions of low relative humidity. It must not be allowed to become wet.

The easiest way to do this is to store the wire in its original packaging in closed metal cabinets, which contain an illuminated 60-watt light bulb. The light bulb’s heat will raise the temperature inside the cabinet by 10°F or so, lowering the relative humidity.

Rolls of wire that are partially used should not be left uncovered on the welding machine overnight. They should be returned to their original packaging. Alternatively, there are plastic spool covers available to mount on most wire feeders. Keeping a spool of wire in the feeder until the

spool has been completely used is fine.

Storing wire in an air-conditioned environment can also cause problems. If the wire, which is relatively cold, is brought out into the shop on a hot, humid day and opened immediately, it is possible for the humid air to condense on the wire. If the wire is stored in an air-conditioned room, be sure to bring it out into the shop and sit unopened until it has warmed up. In fact, storage in a dehumidified room is preferable to storage in an air-conditioned room. However, neither is essential if the wire is stored as recommended above.

Weaving and In-Line Oscillation

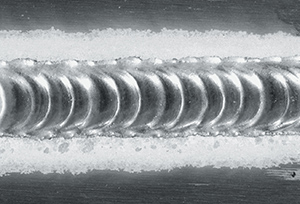

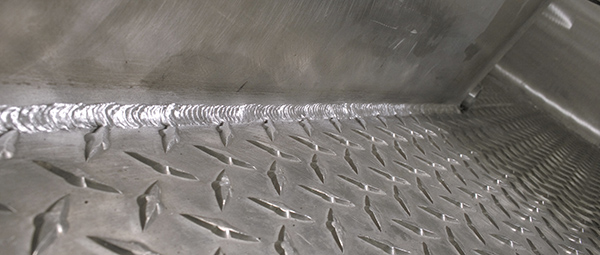

While everyone agrees that side-to-side weaving across the seam produces excessive heat input and should not be used, it is very common in the some industries for welders to use an in-line weave or “shuffle.” The purpose of the shuffle is to produce the “stacked dime” appearance if the weld isn’t too large. The main advantage of this technique is that it produces obvious regularly spaced weld ripples similar to a GTAW weld. However, the shuffle does not produce improved penetration or cleaning, or a better weld quality. It is merely cosmetic.

Shuffling is fine as long as the amplitude of the shuffle is controlled. It should be about 1/8 inch to 3/16 inch (3 mm to 5mm). If the amplitude of the shuffle is greater than this, it can produce low spots between each weld ripple. This can reduce the weld throat and is not acceptable.

Make Sure You Are Using the Correct Filler Alloy

The most common applications in shipbuilding are joining one of the 5XXX Al-Mg sheet/plate alloys, such as 5052, 5154, 5454 or 5083, to themselves or for joining one of the 6XXX extrusion alloys to a 5XXX alloy.

For joining the 5XXX alloys to themselves, the correct filler is 5554 for welding 5154 or 5454. For welding 5052, 5356 should be used. For welding 5083, which has a higher strength, 5556 or 5183 is recommended because 5356 does not quite match the strength of 5083. 4043 filler should not be used to weld 5XXX alloys, except for 5052, which has low Mg content.

For joining 5XXX sheet or plate to the 6XXX extrusion alloys, such as 6061-T6, the recommended filler alloys are 5356 or 5554. 4043 filler is not commonly used in shipbuilding because of its lower corrosion resistance. There is no advantage in using the higher strength fillers 5183 or 5556 in this application. Some suppliers will try to sell these alloys for this application because they are higher cost, but they are not beneficial.

We have attempted to give some guidance that is helpful to aluminum welders in the shipbuilding industry, though it is by no means comprehensive. Hopefully, this article has given you a few more ideas on how to improve your aluminum shipbuilding welding skills.