Controlling Exposure to Manganese in Welding Fume

OVERVIEW

The two most common US exposure limits are established by OSHA in the form of Permissible Exposure Limits (PEL) and by the American Conference of Governmental Industrial Hygienists (ACGIH) in the form of Threshold Limit Values (TLV). Your employer is required by OSHA to keep exposures below the PEL and may choose voluntarily to keep exposures below the TLV, if it’s lower than the PEL.

This white paper will focus on what employers and welders can do to help control exposure levels to welding fumes, and highlight manganese in particular because in 2013 the ACGIH adopted a new, lower TLV for manganese.

THE NEW TLV FOR MANGANESE

The Permissible Exposure Limit (PEL) of 5.0 mg/m3, ceiling, remains the US exposure limit for manganese enforced by OSHA. Lincoln Electric continues to recommend that exposures in the workplace be controlled to the TLV or the applicable regulatory exposure limit standard (in the US, the PEL), whichever is the more conservative.

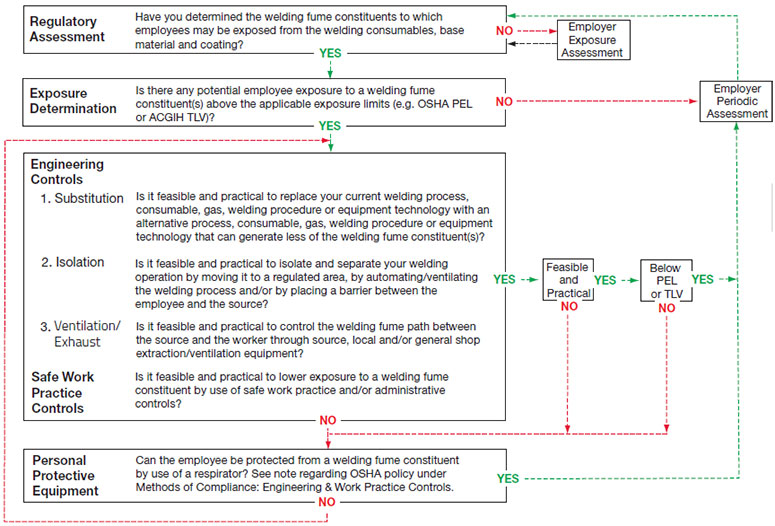

METHODS FOR CONTROLLING EXPOSURE

Be sure to check the safety data sheet for the products you use. It’s important to not only evaluate the exposure to the welder, but also material handlers, stock keepers and others working in the facility. Fumes are not exclusive to the welder’s work area as they may migrate to areas where other workers may be exposed. When measuring to a TLV limit, the measurements should be averaged throughout the worker’s shift, which is typically eight hours. Where exposures are assessed to be over the TLV, many approaches can be considered to reduce exposures to acceptable levels.

ENGINEERING CONTROLS

WORK PRACTICE CONTROLS

PERSONAL PROTECTIVE EQUIPMENT (PPE)

Many Lincoln Electric material safety data sheets (MSDS) have a Maximum Fume Exposure™ guideline number and the substance upon which it is determined. The purpose of this guideline is to provide the industrial hygienist with insight into which material is likely to be the principal chemical of hygienic significance detected during fume monitoring and the approximate total fume exposure at which the recommended exposure limit is reached. It’s provided as a tool to be used for helping to control the exposure levels in the workplace. The lower the fume guideline number, the better the engineering controls must be to control the exposure.

The Lincoln Electric Maximum Fume Exposure guideline number does not consider any paint or plating on the work because that information is only available when the specific application is known. It is best to remove paint, plating or other contaminants from the base metal before welding, if that is possible. If the base metal cannot be cleaned before welding, the composition of the coating should be evaluated. In addition, the fumes should be collected and analyzed to determine what compounds from the surface preparation are in the fume, and to measure the amount of exposure to those compounds.

FREQUENTLY ASKED QUESTIONS

Why did the American Conference of Governmental Industrial Hygienists (ACGIH) decide to make this change which lowers the TLV for respirable and inhalable manganese?

The ACGIH’s change in the manganese particulate TLVs appears to be based on reports of pre-clinical neurobehavioral and neuropsychological changes in workers exposed to chronic low levels of manganese. Some reviewers have pointed out methodological flaws in these studies and that they have demonstrated notably inconsistent findings after several decades of research. Nevertheless, the ACGIH decided to move forward with the reduction in its TLV for manganese.

Does the new Threshold Limit Value (TLV) distinguish manganese in welding fume from other types of manganese?

No, the new TLV does not distinguish between the form of manganese found in welding fume and other forms of manganese.

Is the TLV a legal or regulatory exposure limit?

No, the TLV is not a regulatory limit such as OSHA’s Permissible Exposure Limit (PEL). Some governmental entities utilize its TLVs in adopting standards. The Permissible Exposure Limit (PEL) of 5.0 mg/m3, ceiling, remains the US exposure limit for manganese enforced by OSHA.

Should we follow the new TLV – and if so – why?

The ACGIH is a long-standing body that is comprised of professional industrial hygienists that review applicable health studies, monitor reports related to the health effects and risks of exposure to compounds encountered in the workplace, and advise regarding safe exposure levels. Lincoln Electric continues to recommend that exposures in the workplace be controlled to the TLV or the applicable regulatory exposure limit standard, whichever is the more conservative.

Do countries outside the U.S. adopt the ACGIH TLV as their legal regulatory exposure limit?

In short, yes. For example, many countries, and the State of California, adopt exposure limits that are equal to the ACGIH TLV. Countries with exposure limit standards equivalent to TLVs include, most Canadian provinces, many European countries, Japan, Malaysia, Mexico and much of South America. Some of these will undoubtedly adopt the new TLV for manganese.

How do I know if a welder’s exposure is below the TLV?

As an initial observation, the welder’s breathing zone and general area should be clear of any visible fume or particulate. The most effective means for confirming that exposures are below the TLV is to have a qualified individual such as a professional industrial hygienist conduct an exposure assessment in your workplace.