PHOENIX INTERNATIONAL: NEW PROCESS FOR WELDING ALUMINUM UNDERWATER

New Process for Welding Aluminum Underwater Will Eliminate Costly,

Time-Consuming Drydocking

Phoenix International and U.S. Navy Pilot Test Program with Help of Lincoln Electric

“The system runs beautifully,” Elliott says, “I attribute that to the nice finish on the wire and the speed at which the power system and wire feed can control the process."

Aluminum vessels are making their way into the U.S. Navy fleet. While repairs to steel-hulled ships on the water are nothing new, working with aluminum presents far greater challenges. Wouldn’t drydocking ease the aluminum-welding process? Yes, it would, but with global reach, U.S. Navy ships can be at nearly any point on earth, and drydocks are rarely nearby.

In addition, the drydocking process plays havoc with the Navy’s intricate deployment scheduling, and as a war-fighting machine, the Navy and its ships must be at the ready and in position at all times. Cost is another consideration, as drydocking is much more expensive than keeping the ship in the water when performing maintenance and repair.

Ship photos used with permission of the U.S. Navy (USS Independence LCS-2) 2012

With drydocking currently as the only option for weld repair of aluminum-hulled ships, the Navy is searching for new solutions. It may have found one with a promising new technique: underwater aluminum gas-metal-arc welding (GMAW) in a hyperbaric chamber.

Phoenix International is performing tests at Bayou Vista, Louisiana, on behalf of the Navy, with a third-party auditor validating the results. Ultimately, the Phoenix International procedures must pass three hyperbaric aluminum-weld tests: 5083 alloy welded to itself, 5083 alloy welded to a 6000-series alloy; and a 6000-series alloy welded to another 6000-series. The project has a huge assist from equipment and consumables supplied by the Lincoln Electric Co. in Cleveland and backed by Lincoln Electric technical support.

Ship photos used with permission of the U.S. Navy (USS Independence LCS-2) 2012

Arose from Sense of Urgency

All-aluminum U.S. Navy Littoral Combat Ships (LCS-2s) began entering service in 2009, creating an urgent need to develop a dependable, certified underwater aluminum welding process.

“Stick welding, or shield-metal-arc welding, does not work well on aluminum, so we had to develop a GMAW procedure for performing underwater dry-chamber aluminum-welding repairs,” explains Justin Pollack, underwater ship husbandry/underwater welding program manager for the Naval Sea Systems Command, and supervisor of salvage and diving for the U.S. Navy.

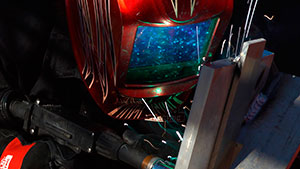

Phoenix International, based in Largo, Md., and holder of the Navy’s Diving Services contract for the past 15 years, has been developing a new process with the Navy for more than two years, with procedure trials now underway. Lincoln has worked closely with Phoenix International on this project, supplying a Power Wave® S350 welder and Power Feed® 25M wire feeder, as well as Lincoln Electric SuperGlaze® 5556 3/64-in. diameter wire. The Power Wave welder and Power Feed feeder are located above the surface of the water on land, connected to a push-pull welding gun with 50 foot gun cable located 24 feet underwater in a hyperbaric chamber.

Underwater Aluminum Welding a Tough Proposition

Aluminum is generally considered much more difficult to weld than steel. For example, aluminum’s high thermal conductivity and low melting point can easily lead to burnthrough and warpage problems if proper procedures are not followed. Aluminum’s high thermal conductivity means the material tends to act as a heat sink, making fusion and penetration more difficult.

In terms of chemical composition, aluminum has a high maximum solubility for hydrogen atoms in the liquid form and a low solubility at the solidification point. This means that even a small amount of hydrogen dissolved in the liquid weld metal will tend to escape as the aluminum solidifies and porosity is likely to occur – a great cause of concern during the welding process.

While welding aluminum on dry land poses a number of challenges, welding in an undersea environment vastly complicates the process. “Porosity is the major problem for aluminum,” says Pollack.

Early on in development of a new procedure, aluminum welds performed on the surface passed X-ray tests, but while performing the same process in the water, “we were getting a ton of porosity,” Pollack explains. “We realized that we have to control the environment. The welders are working around water, so humidity is an issue, and because they are working at depth, pressure is increased.”

Ken Elliott, welding manager for Phoenix International, echoes the concerns about pressure. “Underwater, a dry environment such as a hyperbaric chamber has an elevated pressure, and elevated pressure will find any route back to ambient pressure,” he says. “The habitat environment is trying to escape. Even through the small space between the wire conduit and the wire itself, pressure tries to escape to the surface, taking contaminants with it.”

Given the pressure variation, impurities in the habitat atmosphere, including moisture, can work their way into the weld, contaminating the weld bead and leading to porosity, which will significantly weaken the welding joint. Beyond that, underwater welding in a hyperbaric chamber presents its own set of challenges.

“The hyperbaric chamber, also known as a habitat, measures about six feet tall by four feet wide and five feet deep,” explains Nathan Martin, welder/diver for Phoenix International. “We are welding in 23 feet of water with everything around us that a normal welder would have. In the chamber, we have a greater sense of how clean to keep the work area. We are covered in hoses and leads and have to make sure that we can make the necessary body movements to weld comfortably, so we practice those before we actually weld.”

Commercial welder/diver Whitney Ehrgott, Martin’s colleague at Phoenix International, agrees, and also has learned to rely on senses beyond sight to create proper welds.

“Our visibility diminishes when welding underwater, so we have to feel and hear the process, and these heightened senses help us to create better welds.”

The Right Process, Procedures and Equipment Make All the Difference

The process and procedures have been carefully selected for easy repeatability anywhere in the world. Accordingly, the team selected procedures that used 100-percent argon as the inert shielding gas. “One project goal was to develop a way to repair an aluminum ship in any theater throughout the world,” explains Elliott. “So we wanted a welding process that would work without using helium in the gas mix. If we can’t find the right gas mix (in different regions, certain gases may not be available), we can’t repair the ship.”

The standard Power Mode™ advanced process on Lincoln Electric’s Power Wave S350 power source lends itself to using 100-percent argon inert gas very easily, according to Elliott, while providing consistent weld penetration with reduced voltage input. Power Mode uses high-speed regulation of output power to deliver rapid response to changes in the arc. The result, according to Lincoln Electric officials, is improved GMAW performance, including low spatter, uniform and consistent bead-wetting, and controlled penetration. It reportedly delivers excellent arc characteristics on aluminum and other alloys such as silicon bronze and nickel alloys.

Getting power and wire to the welding gun, with a feeding distance in this application of 50 feet from the wire feeder, places great demand on Lincoln Electric’s Power Feed 25M wire feeder and SuperGlaze 5556 3/64-in.-diameter wire.

“Lincoln has provided true 100-foot separation between the power source and wire feeder,” explains Elliott, “and by using a 50-foot push-pull gun on top of that we can get huge separation from where we need to plug in and get power to the actual arc.”

“Also, we have not experienced wire failure in terms of pushing or pulling it through a 50-foot gun cable,” Elliott continues. “A 50-foot gun cable is essential in repairing the ships in the water, and 50 feet is the extreme distance at which you can push-pull any soft material like aluminum."

Elliott reports that the team has experienced smooth wire feeding, with no wire-dross buildup on slave rolls and no undue wear on spring-loaded contact tips that represent the final element of the welding circuit. Lincoln Electric SuperGlaze aluminum wires benefit from proprietary wire surface preparation during manufacturing, resulting in an extremely smooth surface that resists common tangling issues at the feeder and wire shaving at the drive rolls or contact tips.

To prevent the habitat atmosphere, with its humidity and other contaminants, from contaminating welds, the Phoenix team has modified some system features without compromising equipment and consumable performance. For example, reports Elliott, though there is no way to completely prevent habitat air and its contaminants from entering the weld area, the crew has placed material at various connecting points of the system’s conduits and gun cables or encased welding leads to avoid unwanted moisture.

“The system runs beautifully,” Elliott says, “I attribute that to the nice finish on the wire and the speed at which the power system and wire feed can control the process. With this lineup, we can achieve 50-foot push-pull flawlessly. We’ve experienced no collapse of column strength and have not had feeding issues with any of the wire in the extended gun cable.”

Dependability Drives Decision-Making

As the trials head toward completion this spring, equipment and consumable dependability have been noted by Navy and Phoenix International officials.

“Aluminum can be welded in a hyperbaric chamber, but cheap, bottom-of-the-line equipment will not get us there,” Elliott reasons. “Lincoln Electric offered the best background and tech support we have seen in a long time, and the machinery is capable of taking some welding nuances out of the formula. Welders can concentrate on their bead profiles instead of thinking about what they have to do because their machines can’t. Factors such as voltage and amperage controls, and wire stickout length come into play and the Lincoln Electric machinery is well suited to handle that and perform some very technical welding.” Lincoln Electric advanced Power Wave welding power sources operate at extremely fast switching speeds, allowing fast response to changing conditions at the arc.

Following the promising results of this research, the Navy has since purchased several Lincoln Electric power sources and wire feeders to enhance and expand its welding program.

“The operation we have is fairly robust, and we need equipment that can work under harsh environments,” says Pollack. In fact, according to Ehrgott, the machines have been running 24 hours per day for the past six months without a problem.

“We initially chose Lincoln Electric because we were looking for a company that could help support this project,” Pollack continues. “It imposed risk on that company in that they would have to let us borrow equipment before we bought. But the equipment and service allowed us to get where we are today. We have bought several machines, including both power sources and wire feeders.”

Elliott agrees with Pollack’s assessment.

“The welding equipment is a huge factor in getting repeatable, 100-percent Class 1 X-ray-quality work,” he says. “The Lincoln Electric machinery we chose for this project has offered that time and again.”