Percentage of Argon in Mixed Shielding Gas Does Matter

Our company recently switched our main flux-core wire to an E71T-12M-JH8 classification wire. It specifies to use only 75% - 80% Ar / balance CO2 shielding gas. We typically use a mix with 88% argon. Is this not recommended? Or is this just one of those cases where we'll need to do some testing on our own for verification?

There are two potential issues with using an 88% argon (Ar) / 12% carbon dioxide (CO2) shielding gas mix with the E71T-12M-JH8 electrode (aka wire). First, using that much argon in the mix with any gas-shielded, flux-cored electrode (see example in Figure 1) can result in an excessive increase in puddle fluidity. The second and greater potential issue, particularly with an American Welding Society (AWS) “T-12” classified electrode, is an elevated weld metal tensile strength level, which could potentially result in weld cracking issues.

Regarding the first issue, gas-shielded, flux-cored electrodes are typically used with either 100% CO2 shielding gas or an argon / CO2 mix (of which 75% Ar / 25% CO2 is the most common in the United States). The addition of argon to the CO2 increases the smoothness of the arc and operator appeal, particularly with out-of-position welding. It produces a smooth spray arc transfer and good puddle fluidity. However, as the percentage of argon in the mix starts to get over approximately 80%, the arc becomes more fluid and “soupy”. It can become more difficult to handle, particularly for vertical up and overhead welding. This is generally an operator appeal or personal preference issue.

As a side note, when using a mixed shielding gas for gas-shielded, flux-cored electrodes, generally the minimum percentage of argon to use with CO2 is 75%. As you decrease the percentage of argon in the mix below this level, you quickly start to lose the operator appeal benefits of the argon. However, you still have to pay a premium for having argon in the gas mix. Many gas-shielded, flux-cored electrodes for use with mixed shielding gas will specify a recommended maximum percentage of argon, while the implied minimum level of argon is 75%.

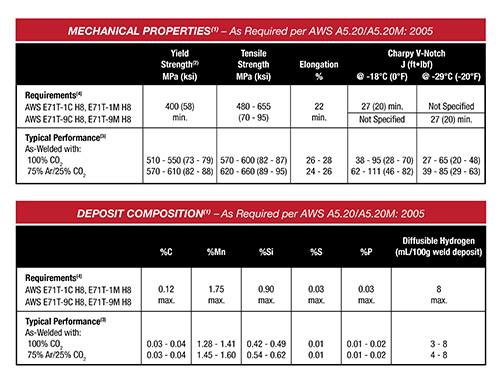

Regarding the second issue, using more than the recommended percentage of argon in the mixed shielding gas can result in higher than expected weld metal tensile strength. First, note that per the AWS filler metal specification, an AWS E71T-12M-JH8 classified electrode (i.e., “T-12” electrode) not only has a minimum tensile strength requirement of 70,000 psi or 70 ksi (483 MPa), it also has a maximum tensile strength requirement of 90,000 psi or 90 ksi (620 MPa). Electrodes with two other very common “T-1” and “T-9” classifications (e.g. E71T-1M / E71T-9M), have a minimum tensile strength requirement of 70 ksi (483 MPa) and maximum tensile strength requirement of 95 ksi (655 MPa).

Second, note the affect that each type of shielding gas has on the deposited weld metal chemistry. CO2 is an active (i.e. reactive) gas. It will react with or “burn up” some of the alloy from the electrode in the arc, resulting in less alloy recovery in the weld metal. This in turn results in a slight decrease in the weld metal’s yield and tensile strength. On the other hand, argon is an inert (i.e., non-reactive) gas. It does not react with the alloys from the electrode in the arc. Therefore, the greater the percentage of argon in an Ar/ CO2 shielding gas mix, the greater the alloy recovery from the electrode in the weld deposit. And the more alloy recovery in the weld deposit, the higher its resulting yield and tensile strengths. This affect can be seen in the published literature of a “dual” type gas-shielded, flux-cored electrode which is designed for use with both 100% CO2 and an Ar/ CO2 mix. Table 1 shows the typical weld deposit composition and mechanical properties of such an electrode. Note the differences, in particular, between manganese (Mn) and silicon (Si) levels, as well as yield and tensile strength between the weld deposits made using 100% CO2 shielding gas and those using 75% Ar / 25% CO2 shielding gas.

Manufacturers of gas-shielded, flux-cored electrodes carefully control the alloy levels in their products such that when used with their recommended percentages of argon in a mixed shielding gas, the resulting yield and tensile strengths of the weld metal will be within the electrode’s allowable minimum and maximum range. However, if you use a higher percentage of argon then recommended, there will be more alloy recovery in the weld metal, resulting in higher strength levels. In general, as the weld metal's tensile strength increases, it becomes less ductile (i.e., more rigid) and therefore more sensitive to cracking as the weldment cools. An additional preheating operation may then be necessary to help reduce the tendency for solidification cracking issues.

Now for a particular welding application, there may be no maximum weld strength requirement. That decision is up to the design engineer for that particular welding application. However, in general, it is not recommended to exceed a gas-shielded, flux-cored electrode manufacturer’s recommendation for maximum percentage of argon used in the mixed shielding gas. With the proper Ar/ CO2 shielding gas mix, the electrode should produce a weld deposit with the specified minimum tensile strength. Using a higher percentage of argon, with a resulting increase in the weld metal’s tensile strength, provides no additional value. However, it does potentially increase the chances of weld cracking issues. For your particular electrode, the recommendation would be to not use a shielding gas with more than 80% argon.