Weld Fusion vs. Weld Penetration

I have heard some people say that with all welding, you must have deep or maximum penetration into the base plate in order for a weld to be strong. If you have shallow penetration, the weld is weaker. The deepest possible weld penetration is always best. Are these statements accurate?

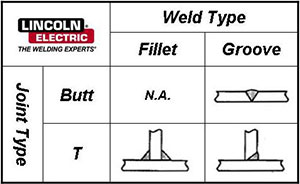

No, it is not accurate to say in all cases that an increase in weld penetration directly correlates to an increase in weld strength (where "strength" is referring to the weld’s yield strength and ultimate tensile strength, both measured in pounds per square inch (psi), kilo psi (ksi) or megapascals (MPa). A weld’s strength is determined by achieving complete fusion and by other factors, depending on the type of weld. This question merits a discussion of the differences between weld “fusion” and weld "penetration". To keep the article fairly short, the discussion will be limited to arc welding, two common types of weld joints (T and butt) and two common types of welds (fillet and groove). See examples in Figure 1.

Figure 1: Commmon Joint and Weld Types

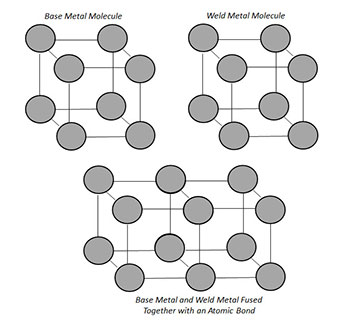

Arc welding is taking two or more separate pieces of metal and joining them into one continuous or homogeneous section. You achieve coalescence, which means to blend or come together. In other words, the purpose of arc welding is to achieve fusion between the initially separate pieces of metal. The American Welding Society (AWS) defines fusion as "The melting together of filler metal and base metal (substrate), or of base metal only which results in coalescence" (ANSI / AWS A3.0 Standard Welding Terms and Definitions). Fusion occurs when you have atomic bonding of the metals. The molecules of each separate piece of metal and the filler metal bond together when you have 1) atomic cleanliness and 2) atomic closeness (see Figure 2). This occurs with arc welding such that the atoms of each piece of metal bond together with shared electrons to become one solid or homogeneous piece of metal.

Figure 2: Atomic Bonding

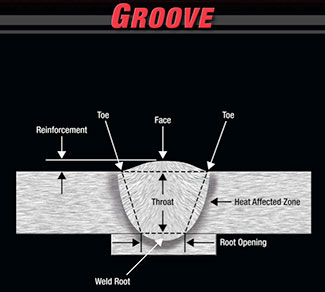

Now on the other hand, penetration, or properly termed depth of fusion, is defined by AWS as, “The distance that fusion extends into the base metal or previous pass from the surface melted during welding”. A cross section of a weld (particularly when etched) will show you the penetration profile of the weld, including the depth and width of penetration (see examples in Figures 3 and 4, which also name and highlight the various parts of a fillet and groove weld). To achieve the proper weld strength, all welding requires complete fusion to occur between the pieces of metal and filler metal, but not all joints require a large depth of fusion or deep penetration. As long as you have achieved complete fusion between the filler metal and the base plates (and when appropriate, the steel backing bar), you have successfully joined the metal together into one homogenous piece. It does not matter if you have deep penetration or shallow penetration. Theoretically (but not realistically), you could even have complete fusion to just the depth of a few molecules and still have welded the pieces together.

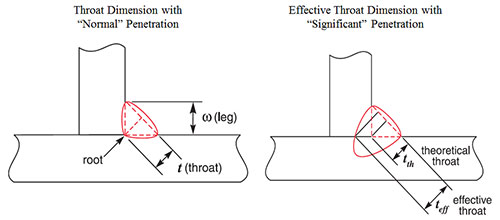

As an example, refer to the T joint and fillet weld in Figure 3. The required weld strength is achieved by having complete fusion and by producing the proper fillet weld size (measured by either the leg length or theoretical throat length) for a given weldment. The appropriate weld size needed to achieve adequate weld strength is determined by the design engineer during the design stage. How this is determined is beyond the scope of this article. However, as the fabricator, as long as you make the proper sized weld per the design specification and achieve complete fusion between the filler metal and base plates, including the root, you have produced a weld of sufficient strength. Weld strength is not determined by the level of penetration into the base plates.

Figure 3: Parts of a Fillet Weld

As another example, refer to the butt joint and complete joint penetration (CJP) single V groove weld in Figure 4. Proper weld strength for a CJP groove weld is achieved by having complete weld fusion and by using the correct strength filler metal (i.e., one that is of at least matching strength to the base metal). Again, weld strength is not determined by the level of penetration into the base plates.

Note also that with a CJP groove weld, the size of the weld does not determine weld strength either, as it does with a fillet weld. Rather, weld size is simply the resulting volume of weld metal necessary to fill in the joint of the proper dimensions (i.e., the degrees of the bevel angle or included angle and width of root opening). Proper joint dimensions are those which allow enough access of the electrode into the joint so that good welding techniques can be used to achieve complete fusion with the base plates (and steel backing bar). In addition, proper joint dimensions are necessary to ensure that the root pass has the correct depth to width ratio (discussed later in this article).

Figure 4: Parts of a Groove Weld

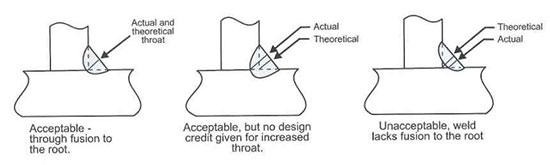

The need to achieve complete fusion has been emphasized in this article. That is because a problem can arise if you have a lack of fusion in any part of the joint. This can be a discontinuity with the sidewall fusion, properly termed joint penetration, or fusion at the root, properly termed root penetration. Incomplete fusion can become a weld defect area, which can affect the weld strength and ultimately lead to weld failure. Figure 5 shows examples of acceptable and unacceptable weld profiles.

Figure 5: Fillet Weld Profiles

While not necessarily related to weld strength, there are situations in which deeper weld penetration can be beneficial. Here are three examples:

Benefit: As stated earlier, you must achieve complete fusion at the root of a weld joint. If the electrode is not aimed properly at the root, the arc length or contact tip to work distance (CTWD) is not held at a consistent distance and/or proper procedures or set up are not used, then lack of fusion issues at the root are more likely to occur. These factors are controlled by the operator’s welding skills, with less experienced welders more likely to have lack of fusion issues. When you have a welding procedure that produces a deeper weld penetration (and a resulting wider penetration profile), you increase the chances of still achieving complete fusion at the root, even with welders that have limited skills. A deeper and broader penetration profile covers a bigger area. Thus you are more likely to still hit the root (i.e., achieve fusion) even if the arc is not focused directly at it.

Benefit: Figure 6 shows examples of CJP groove welds in a butt joint with a root face dimension (i.e., the square edge or non-beveled portion of the plate edges in a butt joint). These joints will be welded from the first side (with one or more passes, depending on plate thickness). Then typically the weldment is flipped over and welded from the second side (again, with one or more passes). To achieve complete joint penetration, the plates must be beveled, as in the double V joint shown in the top picture. Or if it is a square edge joint (shown in bottom picture), then after the first side is welded, the second side of joint must first be back gouged to sound weld metal. Then the second side is welded. If welding procedures that produced a deeper weld penetration were used, then the depth of the joint bevels would not need to be as deep, making the root face longer. Or in the case of square edges, not as much base plate on the second side would need to be removed by back gouging before sound weld metal was reached. In either case, the volume of weld metal required to fill the joint would be reduced. This reduces both the amount of filler metal required to fill the joint and the welding time. Less welding would also reduce potential plate warpage issues.

Figure 6: Joints Requiring Penetration

Benefit: For fillet welds with a flat face and even leg sizes, the distance from the weld face to the root is called the theoretical throat. If you achieve fusion beyond the root, then the actual or effective throat length increases (see Figure 3 for identification of the theoretical and actual throats). Generally no design credit of extra weld strength is given for normal root penetration. However, if significant and consistent root penetration can be achieved, which significantly increases the effective throat depth, then the fillet leg size can be reduced without sacrificing weld strength (see example in Figure 7). Deeper weld penetration does not produce a fillet weld with more weld strength. Rather, it allows a smaller fillet weld to be made with the same strength level as a larger fillet weld made with less weld penetration. Smaller fillet welds decrease the amount of weld metal needed, and may even allow for increased travel speeds. This benefit could be potentially realized by using the Submerged Arc Welding (SAW) process, known for its deep penetration capabilities. Other arc welding processes can be capable of achieving deep penetration as well. However, the fabrication shop must be capable of producing the deeper penetration level on a consistent basis, so this concept may not always be applicable. This Welding Innovations article from the James F. Lincoln Foundation website discusses this topic in more detail.

Figure 7: Greater Effective Throat Produced with Significantly Deeper Weld Penetration

There are also situations in which deeper weld penetration can be detrimental. Here are three examples:

Limitation: Deep penetration can be troublesome when burn through is a concern. When welding on thin material, such as gauge thickness sheet metal, too much penetration can cause the weld to burn all the way through the joint and fall out the bottom. In other cases, a thin root pass is made in an open root joint (e.g., pipe joint). If the second pass has too much penetration, burning through the root pass can be an issue.

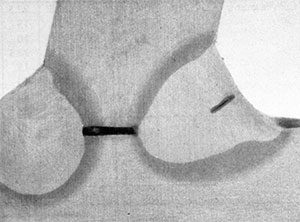

Limitation: If penetration is too deep, centerline cracking (a form of hot cracking) may become an issue. See Figure 8 for an example of a centerline crack in a fillet weld. A balance must be maintained between the depth of penetration and the width of the root pass. The depth to width ratio (W/D ratio) should not exceed 1 to 1.2. This keeps the shape of the weld fairly uniform. As the weld metal solidifies, the shrinkage stresses are thus fairly uniform in all directions. However, if the weld is significantly deeper than wide, then the shrinkage stresses are unequal and the weld will crack in the center of the bead as a result.

Figure 8: Deep Penetration Weld with Centerline Crack Due to Insufficient W/D Ratio

Limitation: Too much admixture with the base plate may also be a problem with deep penetration welds. As penetration increases, so does the volume of base plate that is melted and combined with the filler metal in the resulting weld puddle. This can possibly add additional elements into the weld puddle that makes the weld more crack sensitive. Examples would include welding on free machining grades of steel with higher levels of sulfur, phosphorus and/or lead. These softer elements have lower melting (and solidification) temperatures than steel. So in the liquid weld puddle, they tend to migrate to the center of the weld where they are the last elements to solidify. This high concentration of softer elements in the center of the weld bead often leads to centerline cracking from the solidification shrinkage stresses of the weld.

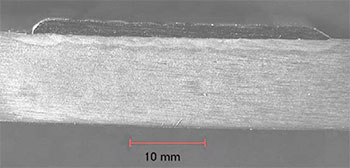

Additionally, in the case of hardfacing or overlay applications, deeper penetration may dilute the weld deposit chemistry and potentially decrease its resulting wear resistance properties. Overlay welds are simply "bead on plate" welds. Figure 9 shows a weld overlay with minimum penetration and thus minimum admixture between the weld metal and base plate. Figure 10 shows a bead on plate weld with deeper penetration and thus much more admixture between the weld metal and base plate.

Figure 9: Weld with Shallow Penetration

Figure 10: Weld with Deep Penetration