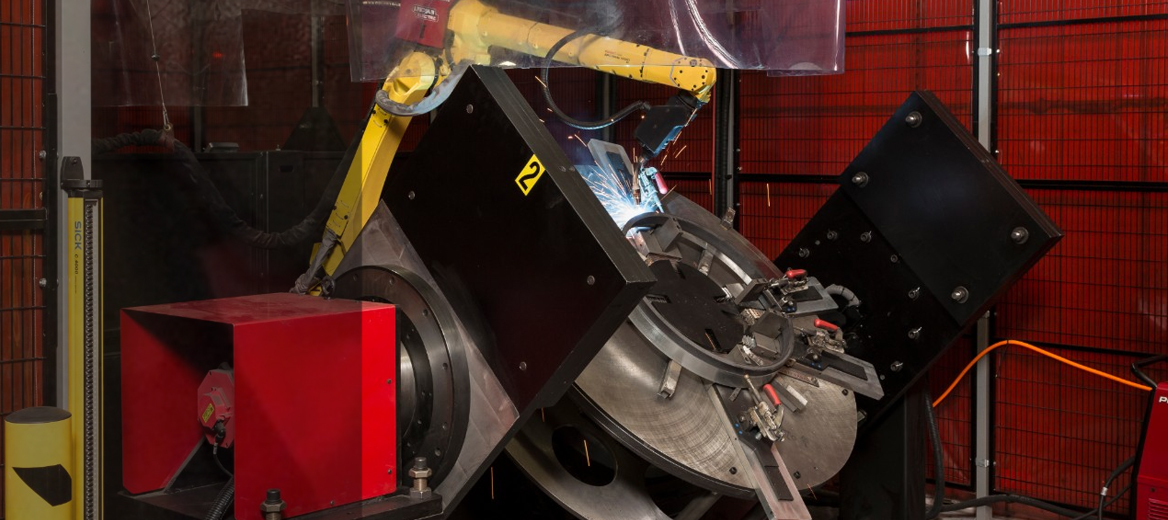

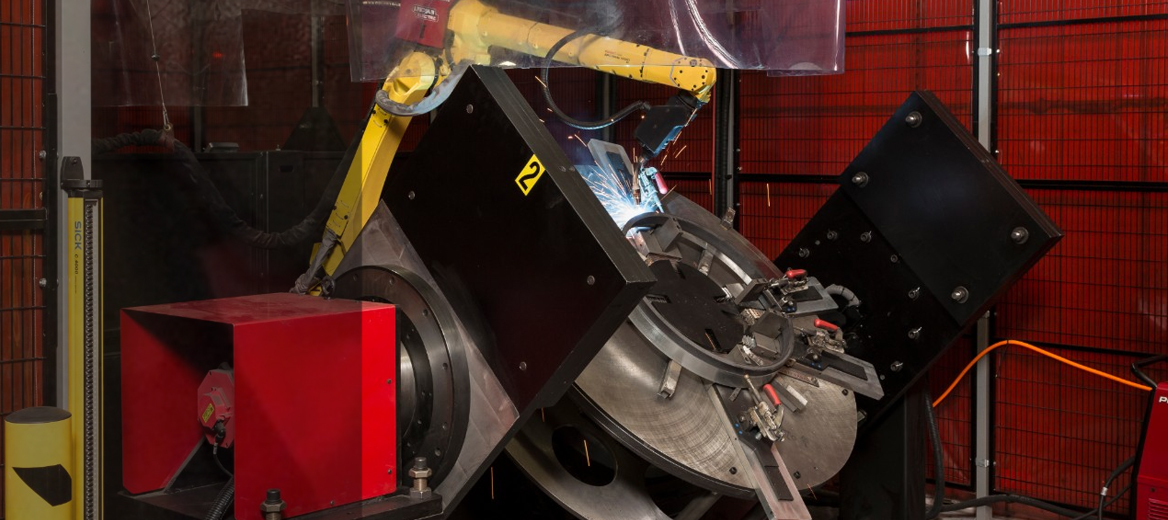

Industry Leading Technology

Power Wave® Manager Standardize your fleets welding procedures Easily save & transfer machine settings Easily configure and select procedure memories Establish parameter range limits and lockouts Allow operators to focus more on welding – less on settings Weld Sequencer™ Utilizing the Power Wave advanced welding platform, Lincoln Electric’s patented Weld Sequencer™ software delivers an intelligent, visually-aided process control solution that optimizes welding performance and quality. Visual work instructions clearly define each assembly step. Continuous on-screen weld metrics & verification. Automatically track weld count, cycle time and deposition.