Welding the Worlds Highest Walkway

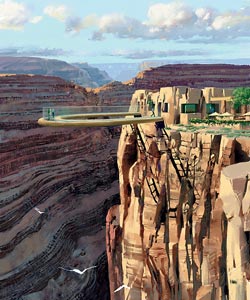

Suspended 4,000 feet above the Colorado River, a new horseshoe-shaped walkway extends 65 feet from the cliff edge of the Grand Canyon at the western rim. The glass floor and sidewalls ensure heart palpitations to anyone vaguely troubled by heights. A 15-second freefall to the canyon floor would span twice the altitude of the world's tallest skyscraper.

For a bridge-like structure, however, the Grand Canyon is an inhospitable place. On a typical day, the unique environment can kick up vertical winds of more than 90 miles per hour.

Securing Bid

To secure the new Grand Canyon Skywalk, engineers cantilevered it to the cliff using 94 steel rods that bore 46 feet into the limestone. It is estimated to withstand 71 million lbs, roughly equal to 71 fully loaded Boeing 747s. But operators have limited the maximum occupancy to 120 people.

Before the project began in 2004, Mark Steel Corporation of Salt Lake City bid on the fabrication work knowing the competition would be fierce. However, engineers for the steel structure and heavy plate shop needed to speed productivity in their existing submerged arc setup to meet the project's tight timetable.

Mark Steel had been using a DC submerged arc setup for jobs of that scope with typical results. Discovering the Power Wave® AC/DC 1000 from The Lincoln Electric Company, Utah's largest fabricator learned that a tandem arc setup, one in AC and another in DC, could boost their productivity welding more than a million pounds of steel for the Skywalk.

With just a few days notice, company engineers flew to Lincoln's world headquarters in Cleveland, Ohio to purchase and train on the new submerged arc welding equipment. Training wrapped up in about a day and the company was then equipped to win the job to fabricate the skywalk's frame and anchor system by demonstrating productivity advantages afforded them by their new technology.

Structural Welding

The structure's steel anchors were flux-cored welded with Lincoln Electric's 5/64 Outershield® 70 and 1/16 Outershield® 71M with 100 percent CO2 shielding gas. The steel sections were 2 inches thick, 8 feet long, 2.5 feet wide and 4.5 feet deep. Joined to form 46-foot anchors, they are now weighted in cement to secure the structure.

While welding the box girders, productivity gains were captured mostly by the tandem submerged arcs. One AC arc and the other DC, operators used digital push-button controls on the Power Feed® 10A to set waveform frequency, balance and amplitude to obtain the optimal balance between penetration and deposition. Welding waveforms could be adjusted to any frequency between 10 and 100 Hertz with the turn of a knob. This allowed operators to pinpoint maximum productivity and quality for varying materials and jobs.

"With just a push of a button, we can go from single wire to tandem, from DC positive to DC negative, and have the ability to control the tandem. It allows us to go to thinner materials, and to weld faster if we need to," said Darwin Childs, welding engineer at Mark Steel.

Embedded software allows opposing arcs to run in tandem without interfering with one another. This translated to a travel speed of 26 to 28 inches per minute. Deposition rates increased from about 28 pounds per hour with the lone DC set up to about 55 pounds per hour, using 3/16th wire on two arcs. This proved particularly helpful for some of the longer welds, which ran 38 to 40 consecutive feet.

Ultrasonic testing revealed the project's weld reject rate at less than 2 percent, said Tony Noah, the Lincoln technical sales representative, who helped Mark Steel install its new equipment and process.

"Even running two simultaneous arcs, they maintained great-looking welds on every weldment," Noah added.

Cost Savings

This narrower gap allowed reduced prep time and grinding with less weld metal required per inch of weld. Overall, Mark Steel saw a productivity gain of 25 to 30 percent and a corresponding reduction in consumable cost. The company also realized a 10 to 15 percent reduction in electrical costs using the inverter-based equipment.

The Skywalk

The Grand Canyon Skywalk is now the highest man-made structure in the world, built with more than one million pounds of steel. It was designed to withstand an 8.0 magnitude earthquake 50 miles away.

To meet the tight deadline, Mark Steel welded around the clock. As such, equipment reliability and technical support was a key consideration in the decision to go with brand new and unfamiliar equipment in the eleventh hour, Childs noted. During production, Childs put his Lincoln sales representative, Tony Noah, on 24/7 standby.

Quality Control

"We were lucky in that we didn't need to constantly monitor everything," Childs said. "We ran around the clock with two 10-hour shifts, but if something had happened, it was good to know we had the diagnostic software and production monitoring capability available in the Power Wave."

As the largest steel fabricator in Utah, Mark Steel took its role seriously as a key player in such a high-profile job.

Company engineers knew the importance of welding the anchor and foundation of the record-breaking tourist attraction they had to be confident in the quality of work.

Mark Steel regularly performs a wide range of work including vessels work on ferryboats, refinery vessels, navy vessels, power plants, heavy equipment, booms and buckets. Childs noted that now that the skywalk project is complete, that the company will begin using the Power Wave® equipment more and more in their other projects.

Results

Tourists courageous enough to walk the Grand Canyon Skywalk will enjoy incredible views and appreciate the remarkable engineering estimated to be complete in late 2006. But for those too timid to venture out past the tourist center, it will be an attraction appreciated from afar.