A Total Systems Approach to Controlling Welding Fumes

Introduction

Operators are exposed to fume and gases when welding, and exposures vary depending upon the process and specific working conditions. Fabricators are under continual pressure to reduce worker exposure to potentially harmful substances in the workplace, including welding fume. This article will address the following:

How welding fume is generated

Coordinating factors that affect fume generation and exposure to fume such as welding design, process, equipment, consumables, gases, work

management and ventilation

Highlights of fume extraction technology

The current U.S. regulatory climate with regard to welding fume

Current published exposure limits for typical components of fume

What Is Welding Fume?

Although many people think of gases and vapors from gasoline or other chemicals as "fume," technically, fume is comprised of very small, solid particles. Since Arc welding usually produces only small concentrations of gases, exposure to gases is seldom a concern except in confined areas. Therefore, the issue of secondary gas production will not be specifically discussed here.

Arc welding creates fume as some of the metal boils from the tip of the electrode and from the surface of molten droplets as they cross the arc. This metal vapor combines with oxygen in the air and solidifies to form tiny fume particles. These particles are visible because of their quantity, but each particle is only between 0.2 and 1.0 micron in size. Since fume primarily comes from the electrode, it consists of oxides of its metals, alloys and flux compounds. In steel welding, therefore, fume is primarily iron oxide and oxides of alloys such as manganese and chromium. With plated or coated metals, some of the fume comes from the weld pool as well. This adds oxides of metals from the base material into the fume such as zinc oxide from welding galvanized steels.

A Total Systems Approach

There are many ways to reduce exposure to welding fume. Each solution addresses part of the welding system. Each solution, however, has its advantages and disadvantages and should be considered in the context of the total system. Likewise, a solution cannot work without proper implementation. The most successful solutions rely on a coordinated effort between managers, engineers, welding supervisors, vendors and especially welders themselves.

Although "fume extraction" may be the first solution that comes to mind, other options should be considered as well. Approaches to controlling welding fume actually fall into two broad categories:

Reducing fume generation

Limiting operator exposure to fume

Reducing Fume Generation

Welding Design Considerations

Limiting the generation of welding fume begins at the design stage. All other things being equal, a properly sized weld will result in the lowest amount of welding fume for a given process and set of procedures. Overwelding, on the other hand, unnecessarily increases welding fume. As the amount of weld metal increases, the amount of fume also increases. The welding engineer should be aware of the role that weld size plays in the creation of fume.

Welding Process Selection

Significant reductions in fume creation can come with a change in the welding process. Therefore, fabricators and welding supervisors should be aware of the impact process selection will have on fume generation. They must also remember, however, that each process offers specific advantages and disadvantages for a given application and a given situation.

Submerged Arc Welding (SAW) contains the majority of the fume (and the arc) under a bed of flux, making it an excellent choice when reducing fume generation is a primary concern. This process has certain limitations, however. SAW requires flat or horizontal positioning, slag cleaning, maintenance of the granular flux, and is most commonly used for mechanized welding of relatively thick steel plate.

Gas Tungsten Arc Welding (GTAW) also produces very little fume, since the filler metal does not carry the welding current, and the arc is very stable. However, manual GTAW is a low deposition rate process requiring highly skilled operators. As such, it is often the process of choice for precision welding or certain special applications. Using GTAW to weld heavy plate would not be practical.

Flux Cored Arc Welding (FCAW) processes are usually considered the largest fume producers due to typically high deposition rates. However, many applications are best served by FCAW precisely because of its high deposition rates, especially in out-of-position applications. Fume generation rates vary widely, depending upon the electrode type, grade, and design. The design of the electrode can have a major impact on the amount of fume that will be generated. Several manufacturers offer reduced fume flux cored electrodes. Research indicates that some metal cored electrodes used with a pulsed current power source can yield low fume generation rates as well.

Gas Metal Arc Welding (GMAW) is a practical option for many applications, from thin sheet metal to heavy plate. Fume generation in GMAW depends upon procedures, droplet transfer, shielding gas, and the grade of electrode used. ER70S-6, for instance, has higher levels of manganese than ER70S-3. Since manganese levels are often a key factor in determining regulatory compliance, this can be a significant issue.

Shielding Gas

The shielding gas also affects arc physics and fume generation. The energy levels required to dissociate and ionize the various gases relates to the excess energy available to boil metal from the electrode and molten droplet. In practice, using 100% CO2 will require a procedure increase of 1-2 volts compared to Argon blends. This adds energy to the arc, boiling off more metal and creating more fume. Although some active gas is needed in GMAW and FCAW of steels, higher percentages of argon in blended gases tend to reduce fume generation. These blends tend to be more expensive than 100% CO2, especially in Europe and Asia.

Waveform Control Technology™

Another way to reduce fume generation is to use one of the various waveform controlling power sources. With pulsed GMAW, for example, less fume is typically produced than with a conventional constant voltage power source. In this mode, the arc is controlled by pulsing the current from a background level to a peak level at a specified frequency. This reduces the total arc energy and decreases the amount of metal that is vaporized, which leads to reduced fume generation.

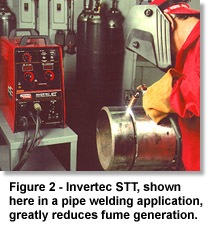

Invertec STT II - pipe welding, low fume applicationLincoln Electric's new STT® inverter is another waveform controlled power source that has led to the creation a new transfer mode: Surface Tension Transfer® (STT) welding. In conventional short-circuit transfer, the current rises to high levels immediately before the droplet detaches from the electrode causing some of the electrode to vaporize. This causes violent droplet detachment and creation of spatter and fume. The STT power source is able to control the current during droplet transfer. When the droplet is about to detach, the current level decreases, and the droplet is pulled into the puddle by surface tension forces resulting is reduced spatter. After detachment, current is then controlled to prevent overheating the tip of the electrode. This control significantly reduces droplet temperatures and increases arc stability. Spatter can be decreased by 90% and fume generation by 50%, compared to conventional short-arc transfer. STT, however, is limited to applications appropriate for short-circuit transfer.

Limiting Operator Exposure to Fume

The second broad category of controlling welding fume covers methods of limiting personnel exposure to the fume. Management will be responsible for initiating the decisions in this category, while employees at various levels of the organization will need cooperate to ensure their success.

Job Sharing

The most direct approach to limiting personnel exposure is simply to limit the amount of time an operator spends welding. This can often be accomplished via job sharing. For example, an operator could spend half a day welding an SAW application, and the remainder of the day welding an FCAW application. Or, the second half of the day might be spent driving a forklift. It is not a cost-free method; after all, twice as many individuals must be trained and qualified as welding operators for any given application. However, it can yield dividends in terms of higher productivity, greater job satisfaction resulting from mastering a variety of tasks, and a more versatile, cross-trained workforce. This simple approach deserves thoughtful consideration by management.

Automated Welding Systems

Robotics and other automated welding systems provide another route to limiting employee exposure to welding fume. Automation can be a viable alternative if the initial capital expense can be justified by higher productivity and improved quality. However, automated welding cells commonly operate at high duty cycles, and employee exposure to fume must still be evaluated.

Fume Extraction Technology

The one method of fume control effective for almost any welding process is ventilation. Since the operator's breathing zone is the critical area, localized ventilation, usually called "fume extraction," is the preferred method. Fume extraction technology falls into two categories: low vacuum/high volume, or high vacuum/low volume.

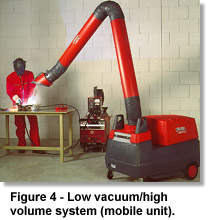

Low vacuum/high volume system (mobile unit) Low Vacuum/High Volume

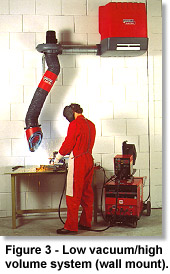

Regular building ventilation systems are low vacuum, high volume systems, sometimes called "low static, high flow." When industry needed better ventilation solutions, many companies modified low vacuum systems for localized ventilation. Hoses 6 to 9 inches (160 - 200 mm) in diameter were added for flexibility and eventually structures were designed to support the hoses and make it easier to position them. Manufacturers began to make these arms with different designs and features, and they are still used in many industries, including the welding industry.

The articulated arms generally move between 600 and 900 cubic feet (900 - 1500 m3/hr) per minute (CFM) of air, but use low vacuum levels (3 to 5 inches water gauge [750 - 1250 Pa]) to minimize power requirements. Water gauge (WG) is a measure of negative pressure: higher numbers mean more negative pressure (more "suction"). With this volume of airflow, the end of the arm can be generally 10 to 15 inches (250 - 375 mm) away from the arc and still capture the fume. Articulated fume extraction arms are produced by a wide range of manufacturers, using 6 inch or 8 inch hose, or hose and tubing combinations. Lengths are typically 7, 10, or 13 feet (2, 3 or 4 m), with boom extensions available. The arms may be wall mounted, attached to mobile units, or incorporated into a centralized system.

For greater capture distances, a larger volume of air is required to achieve the necessary "capture velocity" and capture the fume. In practice, however, longer capture distances may mean that breathing zone exposure is compromised. Overhead hoods, for example, capture most of the fume, but only after it has passed through the breathing zone of the operator.

Cross draft ventilation is a variation of overhead hood technology. These systems use a plenum with openings to the side of the work space, rather than above it. Therefore, the fume moves sideways, away from the operator's breathing zone. These systems can be effective for small booths when small parts are being welded. The CFM required for effectiveness varies depending upon the installation design, but frequently can be 1,000 CFM or higher.

There are, however, certain disadvantages associated with the low vacuum systems. For example, in systems incorporating articulated fume extraction arms, the operator must stop to reposition the arm over each weld area, which diminishes productivity. These arms also have limited reach, commonly 10 to 13 feet. The high volume of air flow requires large hoses, and ductwork ranging from 8 to 36 inches in diameter or more, depending upon the installation. Exhausting air outside often requires make-up air systems and make-up air heaters. Filtration systems are large due to the high air volume being processed.

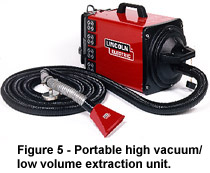

High Vacuum/Low Volume

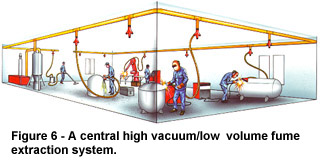

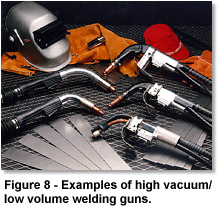

High vacuum/low volume fume extraction systems are much more specific to point-source applications such as welding. Their chief advantage: they remove the fume directly at the source, within inches of the arc. This means that fume is captured before it can reach the operator's breathing zone or disperse into the room. Because of the close proximity to the source, fume extraction can be achieved with lower airflow rates, typically 80 to 100 CFM for suction nozzles, depending upon the design, and 35 to 60 CFM for integrated fume extraction guns. The vacuum level is high (40 to 70 inches WG), permitting the use of hose featuring longer lengths (10 to 25 feet) and smaller diameters (1.25 to 1.75 inches). High vacuum equipment ranges from small, portable units to mobile three-phase systems, to large, centralized systems.

There are two methods of high vacuum extraction: welding guns with built-in extraction, or separate suction nozzles of various designs. (Photo.) Suction nozzles are positioned near the weld, typically with magnets, and commonly use capture distances of less than four inches. Fume extraction guns use fume capture nozzles built into the gun tube and handle. Therefore, no repositioning is required, since the suction automatically follows the arc.

High vacuum extraction, like other solutions, has its limitations. Although manufacturers have greatly improved designs, fume extraction guns are larger than regular welding guns. Furthermore, fume guns do not control residual fume and smoke, since the gun is moved away immediately after welding is completed. Finally, unless they are set in weld fixtures, high vacuum suction nozzles also require repositioning.

Nevertheless, high vacuum/low volume methods of fume extraction offer significant advantages to welding fabricators. Of chief importance is the removal of fume right at its source, before it can reach the operator's breathing zone. Since fume guns eliminate the repositioning required by articulated arms or suction nozzles, productivity is not directly reduced.

Many other advantages come from reducing the total amount of airflow required. A lower volume of air means smaller ductwork, smaller hoses, much smaller filter systems, and less strain on make-up air systems if the air is exhausted outside. This translates into lower material, installation and maintenance costs. A typical low vacuum system for twenty stations, for instance, might require an airflow rate of 12,000 CFM, whereas a high vacuum system serving the same facility could require an airflow rate as low as 1,200 CFM.

After fume is removed from the source, it is either exhausted directly to the atmosphere or is passed through an electrostatic or cartridge filter. Because electrostatic filters lose efficiency if they are not frequently washed, the welding industry primarily uses more easily maintained cartridge filters. Most cartridge filters have a high efficiency level, usually 98% or higher. Although cartridges classified as "HEPA" have extremely high efficiency when new, they are expensive and have shorter life. HEPA filters are normally not necessary in fume extraction equipment, since capture efficiency has a much greater impact on breathing zone exposure than filtration efficiency.

Regulatory Bodies

Two major types of organizations study and regulate exposure to welding fume and other particulates in the workplace: industrial health organizations, and government regulatory agencies. In the U.S., two major industrial health organizations are the American Conference of Governmental and Industrial Hygienists (ACGIH) and the National Institute of Occupational Safety and Health (NIOSH). They set exposure limits for a variety of materials, including those found in welding fume. The ACGIH calls their limit the Threshold Limit Value (TLV). The TLV is influential in industry and is a standard followed by most insurance companies. As important as the TLV is, however, it is not enforceable by law. The Occupational Safety and Health Administration (OSHA) is the only organization that can establish legally enforceable limits for exposure to chemicals in the workplace. At both state and federal levels, OSHA's mandatory Permissible Exposure Limits (PEL) place tough demands on the welding industry.

Exposure Limits

The limits for fume exposure set by OSHA and others are measured in milligrams of particulate per cubic meter of air (mg/m3). The total amount of fume produced is not limited, but rather the concentration of fume is limited. During facility testing, a sampling device is placed in the breathing zone of the operator (e.g., the welding hood, not on the lapel). At the end of the operator's shift, a number is calculated that reflects an 8-hour Time Weighted Average (TWA) of the fume concentration in the operator's breathing zone, in mg/m3.

Since this method focuses on breathing zone exposure, the results are highly unpredictable, even when the process, procedure and other influences are consistent. Therefore, to ensure compliance with exposure limits, companies should test their own operators while they are welding in everyday applications to obtain an accurate concentration value. The results can then be compared to benchmarks such as the TLV or PEL. If the number is higher than the standard, then that company is out of compliance.

Listed in Table 1 are the current welding fume exposure limits as specified by OSHA and ACGIH. Note that the table does not contain a PEL for total welding fume. The PEL of 5 mg/m3 established in 1989 was challenged in a lawsuit, and is no longer enforced.

|

Table 1. Exposure Guidelines for Materials Sometimes Found in Welding Fume |

||

| ACGIH(1) TLV (mg/m3) |

OSHA(2) PEL (mg/m3) |

|

| Welding Fume | 5.0 | |

| Iron Oxide, as Fe | 5.0 | 10.0 |

| Manganese (all forms) | 0.2 | 1.0(3) 5.0 (c) |

| Chromium III compounds | 0.5 | 0.5 |

| Chromium VI compounds, sol | 0.05 | 0.05 (c) |

| Chromium VI compounds, insol | 0.01 | 0.5 (c) NIC.0005 - .005 (both forms) |

| Nickel, insol compounds, as N | (1.0) 0.5 NIC | 1.0 |

| Aluminum, Welding Fumes, as Al | 5.0 | |

| Zinc Oxide, fume | 5.0 10.0 (c) | 5.0 |

| Barium compounds, sol, as Ba | 0.5 | 0.5 |

| Beryllium & compounds, as Be | 0.002 .01(c) | 0.002 .005(c) |

| Cadmium Oxide, as Cd | 0.002 | 0.005 |

| Cobalt oxide, as Co | 0.02 | 0.1 |

| Copper fume, as Cu | 0.2 | 0.1 |

| Flourides, as F | 2.5 | 2.5 |

| Magnesium oxide fume | 10.0 | 15.0 total particulate |

| Molybdenum, insol compounds, as Mo | 10.0 | 15.0 total particulate |

| Tin oxide | 2.0 | 2.0 |

| Vanadium pentoxide, as V2O5 | 0.05 | 0.1(c) |

(1) Threshold Limit Value set by ACGIH (American Conference of Governmental Industrial Hygenists) based upon 8 hour TWA (Time Weighted Average), as of 9/98.

(2) OSHA Permissable Exposure Limit based upon 8 hour TWA, as of 9/98.

(3) Short Term Exposure Limit (STEL) for Manganese, based on a 15 minute TWA, is 3 mg/m3

(c) Maximum Exposure Concentration: not to be exceeded at any time (not a TWA).

NIC - Notice of intended changes

Manganese and chromium are two examples of materials which have strict time exposure limits as well. When limits are measured on an 8-hour TWA, an operator may be exposed to high concentrations in the morning, but the facility may still be in compliance if concentrations are lower in the afternoon. The limits for certain forms of chromium are "ceilings," meaning that any overexposure during the day will cause the facility to fail compliance.

Since the U.S. regulatory climate regarding welding fume depends greatly upon the specific state, local regulators should always be contacted for relevant information. Companies should check the Material Safety Data Sheet (MSDS) for the welding electrode they use. The MSDS report will show not only the composition of the electrode, but also the components of welding fume that can be created by the welding process. The report also shows the TLV and PEL for each item, and gives valuable information concerning health risks and other reference data. The only way to get a clear picture of where a company stands, however, is testing operators while they are welding in the company's actual facilities.

Conclusion

While exposure to fume can be an issue in any welding application, no one solution is the best for all of them. Each solution only addresses part of the welding system and has its advantages and disadvantages. The best solution will be found when managers, engineers, welding supervisors, vendors and welders work together to meet the needs of the company with a total systems approach