Tandem MIG Process

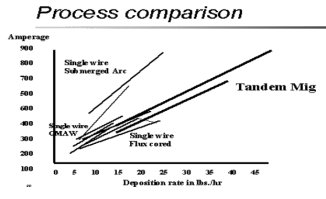

The dual-wire Tandem MIG™ process continues to gain popularity as a means to increase production in automated arc welding applications. The process follows trends established early in the welding industry of reducing welding costs by developing dual-wire processes for greater productivity. Early developments in multiple wire welding focused on the submerged arc process. The availability of high-powered inverter power sources and Waveform Control Technology™ has enabled dual-wire welding using the MIG (GMAW) process.

Since the introduction of Tandem MIG in the early 1990s, the estimated installed base of dual wire MIG (GMAW) systems has grown to over 1,000 units worldwide. The majority of the systems installed have replaced single-wire processes that had been pushed to the extreme high end of the useable operating range in an attempt to improve productivity and lower cost by depositing as much metal as possible in the shortest time frame. Tandem MIG extends the welding productivity range beyond that possible with conventional single-wire processes. A comparison of weld metal deposit rates of popular single wire processes to that of Tandem MIG demonstrates the possible production gains associated with the Tandem MIG process.

Process Fundamentals

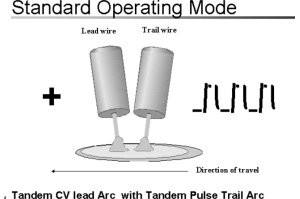

The Tandem MIG process employs two electrically isolated wire electrodes positioned in line, one behind the other, in the direction of welding. The first electrode is referred to as the lead electrode and the second electrode in line is referred to as the trail electrode. The spacing between the two wires is usually less than ½ inch so that both welding arcs are delivering to a common weld puddle. The function of the lead wire is to generate the majority of the base plate penetration, while the trail wire performs the function of controlling the weld puddle for bead contour, edge wetting and adding to the overall weld metal deposit rate.

The process works best with a large diameter lead wire and a small diameter trail wire. The larger lead wire may represent as much as 65% of the total deposition rate, while providing greater penetration. The smaller, trail welding wire is focused on the trail edge of the weld puddle. The trail wire is typically smaller in diameter and therefore draws less current. This helps to control the shared weld puddle and aids in keeping it cool.

A common compromise is to specify the lead and trail welding wires to be the same diameter to satisfy inventory constraints or because the direction of welding must be reversed somewhere on the weldment. Satisfactory operation may be achieved with this compromise but the maximum travel speed is limited and the robustness of the process is reduced.

Tandem MIG depends on specialized power source control software that facilitates the stable operation of two independent welding arcs working in close proximity. The power source must be controlled to stabilize the disruptive electromagnetic influences that cause severe instability when two unregulated direct currents (DC) welding arcs are operated close together.

In the standard operating mode, the lead arc is programmed for a Tandem MIG DC positive constant voltage mode, and the trail for operation in a Tandem MIG DC positive pulse mode. The constant voltage lead arc is desirable to maximize penetration and travel speed. The lower heat input pulsed trail arc is instrumental in minimizing possible electromagnetic arc interference between the two arcs, as well as cooling and controlling the common molten weld puddle that is generated.

The combination of the constant voltage (CV) lead and Tandem MIG pulse trail configuration provides a wide operating range. The lead and trail arc procedures may be changed independently to achieve a balance between penetration and fill.

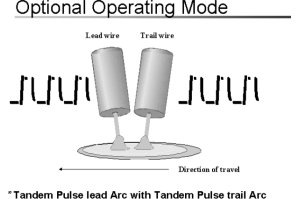

A second potential configuration calls for operating both the lead and trail welding wires in a Tandem MIG pulse mode. This configuration is typically used to manage total process heat input on thin gauge material and other heat sensitive applications. This configuration requires synchronization of the pulse frequency of both electrodes so that the peak of each pulse on one of the arcs occurs during the background of the other arc.

Sychronization implies that both the lead and trail arcs must be operated at the same frequency (or frequencies that are an integer multiple of each other). The requirement imposes strict operation constraints and the process must be carefully applied.

- Again, the lead and trail procedures must be programmed to operate at the same frequencies or at integer multiples of each other

- To increase or decrease deposition, the lead and trail wire feed speeds must be varied together. This reduces the degree of independence between penetration and fill

- Arc voltage regulation cannot be achieved by dynamically varying the frequency

Equipment configuration

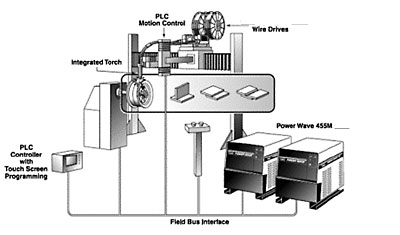

The Tandem MIG equipment is configured to provide individual parameter control for each of two separate, and electrically isolated, welding arcs. This requires a pairing of all equipment; two specially designed high-speed inverter power sources, two wire drives, two separate welding wire pay-off sources and a Tandem MIG welding torch. The power sources used for this process rely on fast digital control and Tandem MIG specific software. Welding parameters are set at the power source via digital communication from either a Programmable Logic Controller (PLC) associated with a dedicated hard automation work cell or by a robot controller.

The Tandem MIG torch is a critical component of the system, engineered with specific contact tip alignment and spacing to achieve proper arc control. Due to the need to withstand the demands of high amperage, high duty cycle production runs the torches are generally rated in terms of the total current flowing in both wires. This rating is typically in the 600-1200 amp range. Additionally, the maximum current for each wire is specified. This rating is typically in the 400-800 amp range. An example of a hard automation equipment configuration would be:

Process Benefits

The increased production benefits of the Tandem MIG process have been used to:

- Justify the cost of automation equipment

- Improve profitability of existing automation

- Reduce the initial capital expense costs of new production lines by reducing the number of weld stations required

- Shorten payback periods associated with new welding automation.

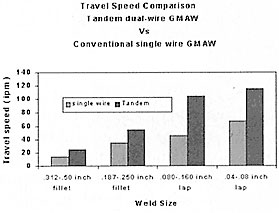

The Tandem MIG process has a wide operating range that can be generally segmented into two catagrories addressing high speed sheet metal welding and heavy plate welding. On sheet metal, the process is often operated at travel speeds in excess of 100 IPM on thin gauge material (.040 - .100 inch). On heavy gage material, weld metal deposition rates exceeding 35 lbs./hr. are possible.

High travel speed applications

The ability to distribute the total welding current across two separate welding wires provides unique benefits for high-speed welding. When pushed to increase travel speeds on thin gauge metal components in industries such as automotive, tank and general sheet metal fabrication, welding operations are faced with one or two quality issues, either burn through or lack of weld metal follow characteristics.

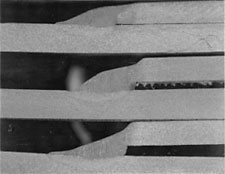

The Tandem process addresses both of these speed-limiting issues. The ability to distribute the necessary welding current over two welding wires allows the lead wire to generate needed penetration while the trail wire rides on the back edge of the weld puddle creating added fill. Also, the trail wire acts as an additional force that pushes the puddle for better follow and wetting capabilities. This trail arc behavior in the shared weld puddle provides excellent gap filling characteristics. Improved gap filling capabilities are of particular value to industries processing high volumes of stamped or formed parts.

The system utilizes robot touch sensing software to locate the weld joint and through-the-arc seam tracking (T.A.S.T.) software option for real-time tracking. The Tandem system welding at an average speed of 60 ipm was installed to replace an older single wire robotic system that was that was averaging 24 ipm. Overall welding speed was increased 150 %.

High deposit rate applications

As illustrated in the previous graph, the Tandem MIG process can on average represent a 30-80% increase in deposition potential when compared to conventional single-wire processes.

The Tandem MIG process typically employs small diameter electrodes. As higher welding currents are applied to the small diameter electrodes (.035- .062 inch) the electrode melt-off rate rises exponentially. The resulting electrode melt-off rate for a given current draw is higher for Tandem MIG than that of a single large diameter electrode. This higher melt-off rate potential and lower amperage draw provides unique benefits for the heavy plate fabricating industry. The high deposit rate obviously provides the means for improved production throughput. The lower heat input can be used effectively to reduce plate distortion and time between passes when controlling inter-pass temperature on mult-pass welds. The process is capable of producing x-ray quality welds with excellent mechanical properties.

Tandem MIG gap filling capabilities. Welds performed at 100-ipm travel speed on .100 inch material Truck side panels being welded with robotic Tandem MIG.

Return on investment

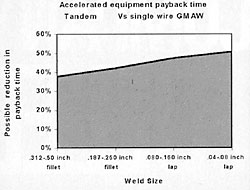

The Tandem MIG process is designed for use on automated welding cells or automated lines. Common host automation is either a hard-automated work cell that has dedicated motion functions or a robotic cell with flexible, programmable motion. Investment in these high-volume production lines is generally a significant capital expenditure that requires detailed analysis and cost justification. Part floor-to-floor time, including welding speed as a critical component, plays an important role in determining if a project can be cost justified. When compared to single-wire processes, Tandem MIG higher travel speed capabilities can assist in cost justifying greater capital expenditures as well as accelerate equipment payback periods.

Tandem MIG has assisted in reducing the cost of new production lines by meeting production needs with fewer welding stations. This is particularly true for high-volume production lines producing automotive components or similar parts where tooling and part handling equipment constitutes a sizeable portion of the initial installation costs. The cost of hydraulic tooling and handling equipment may be reduced by using fewer weld stations based on the higher per-station throughput of Tandem MIG. Additionally, the expense of up-keep and maintenance of duplicate tooling sets to insure consistent part dimensions is minimized.

Truck bolster plates being welded with automated Tandem MIG. The 8-foot long bolsters require a 5/16 inch fillet weld placed on both sides of a 3/8 inch vertical support member. Tandem MIG was able to increase production from 5-6 units per day to 25 units per day. Process uses two .045 dia welding wires depositing 28 lbs. per hour. Production was increased over 300%.

Production cells welding large components must be cost justified in a different way based more on welding time and not part count. The heavy equipment industry, which was the first to embrace the Tandem MIG process, typically utilizes large robotic work cells that include expensive positioners to handle the large and heavy weldments that often take two or more hours to weld. Most weldments must be placed in the flat or horizontal position. This requires the use of large positioners and makes the use of multiple robots per cell difficult. Tandem MIG has repeatedly been used to replace single-wire robotic systems welding at averaging deposit rates in the range of 15-20 lbs./hr. with Tandem MIG operating in the 28-34 lbs./hr range.

The increased weld metal deposit rate has been used to justify the cost of purchasing new more technically sophisticated workstations.

Tandem MIG continues to benefit a number of industries, from companies welding thin sheet metal automotive components to companies performing multi-pass welding of large earth moving equipment and offshore drilling rigs.